Rudders. Just about every warship has them, but rudders vary considerably from one design to the next. Extraordinarily little thought is given to these devices that are hidden away from view underwater. However, rudders are a critical component of warship design. In this article on warship technology, we will look at some of the various rudder designs used by warships. In addition, we will examine some of the factors that have influenced warship rudder design.

What is a Rudder?

First and foremost, what is a rudder? In the most basic of terms, a rudder is a flat surface that is connected to the ship’s hull by a hinge. As the ship’s hull moves, water flows over the rudder. By turning the rudder, the water flows into the rudder and is redirected by it. The force of water pushes against the rudder, causing the stern of the ship to be veered away (For example: Turning the rudder to port, causes the stern of the ship to be pushed to starboard. This in turn causes the ship to gradually turn to port).

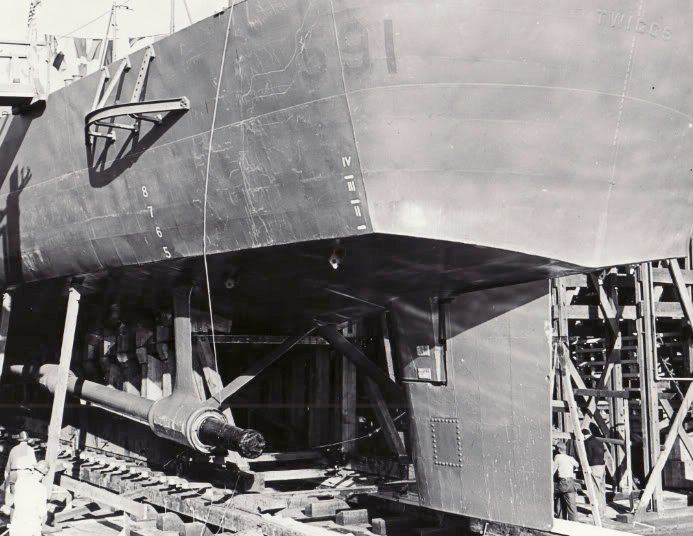

Rudders are typically placed at the stern of a ship. In this location, they better impart yaw on the hull. In addition, the movement of water provided by the thrust of the ship’s screws can also be harnessed to provide better flow to the rudder. Designers often attempted to place the rudder directly behind the screw to provide maximum efficiency.

Rudder Styles

Standard Rudder

The most simple form of the modern rudder is a simple sheet of metal or wood attached to the hull via a mechanism at its forward edge. The entire rudder pivots behind the hinge (Its axis of rotation). While generally the most simple rudder design, it is at a disadvantage due to the immense force of water acting upon the entire length of the rudder. This places a lot of stress on the mechanism that turns the rudder. In addition, more effort is needed to turn the rudder. This can lead to lower agility as the rudder takes longer to turn.

These rudders can be attached to the hull in a variety of ways. The entire forward edge can be attached directly to the hull. The rudder can also be attached to the hull by a post at its upper edge. These rudders, appropriately called “hanging rudders”, have the appearance of hanging from the ship’s hull. They may be supported along the bottom edge by a separate strut or spar that extends out from the hull.

Balanced Rudder

Invented by the renowned British engineer Isambard Kingdom Brunel, the balanced rudder design greatly improved performance. The balanced rudder saw its axis moved away from the forward edge. With the axis moved closer to the center of the rudder, the forward edge of the rudder is rotated opposite of the rear. This causes the flow of water to press into the forward edge, adding a degree of counterbalance to the forces acting on the rear. This counterbalancing element made the balanced rudder easier to turn, reducing the effort needed to turn the ship. This increased agility and made ships more responsive to helm commands.

Balanced rudders, unlike the standard unbalanced design, typically only come in the hanging form. This is due to need for the rudder to protrude past its axis.

Multiple Rudders

As ships got larger, rudders needed a larger surface to produce enough force to turn the hull. Larger rudders would also help improve agility as they would grab more of the water flowing over them. The problem was that a rudder of sufficient size might not be practical due to size constaints. For this reason, designers began incorporating multiple rudders aboard warships. As with so many other design considerations, adding more rudders provided additional benefits as well as a few disadvantages.

Twin Rudders

The logical next step over the single rudder was the twin rudder. Two rudders would help each rudder remain relatively small while retaining the required surface area. In addition, two smaller rudders would allow for their respective steering equipment to remain smaller as opposed to the equipment needed for one large rudder. Twin rudders also provided a measure of safety. If one rudder was incapacitated, the other rudder could potentially allow the ship to remain under control. During the 1900s, warships equipped with twin rudders became very common.

Despite their benefits however, twin rudders also presented some challenges. They were located closer to the outer edges of the hull, exposing them to the possibility of more damage. Depending on how close the rudders were to each other, they could both become incapacitated in the event of battle damage. This famously occurred on the German battleship Bismarck during the Second World War. Last but not least, the use of twin rudders could produce more drag, robbing the ship of some performance.

To address some of these issues, designers experimented with the design, placement, and shape of twin rudders. Most notably was placing both rudders inline with one another as opposed to placing them side by side. Japan adopted this inline arrangement aboard the Yamato class battleships. It was hoped that the layout would reduce drag, while retaining the redundancy of two rudders as well as the agility. Unfortunately, the smaller forward rudder was too small to turn the ship in the event of the main rudder becoming disabled.

Three or More Rudders

Based on the benefits of two rudders, some designers took it a step further and added even more rudders. Three rudders were trialed on several warships, ranging from small torpedo boats to giant battleships. The Germans adopted three rudders aboard their schnellboots for performance reasons. In Italy, designers adopted a unique three rudder layout aboard their Littorio class battleships. A main rudder was supported by two outboard wing rudders. These rudders, being widely spaced, granted the Littorio class a level of protection that was unavailable to other battleships. If one rudder was disabled, the other two rudders could help the battleships maintain control. Italian designers had helped counter one of the weakest spots on a battleship through simple redundancy.

More modern ships have also experimented with multiple rudders. The first nuclear aircraft carrier in the United States Navy, USS Enterprise (CVN-65), was equipped with no less than four rudders. Details for this arrangement are scare, but the location of the rudders (one placed directly behind each screw) would have certainly granted a higher level of agility. However, subsequent United States carriers have reverted back to a twin rudder arrangement. Multiple rudders, while offering some benefits, do create considerably more drag. The twin rudder arrangement has shown itself to be the best compromise of performance and efficiency.

Alternatives to Rudders

While rudders have become more advanced throughout the history of ship design, some of the most modern ships have gotten rid of them entirely. A relatively new technology is the azimuth thruster. The screw is housed in a pod that can be rotated horizontally over a wide range of angles. Due to its ability to direct thrust in whatever direction is needed, ships equipped with azimuth thrusters have no need for a traditional rudder. These ships are much more agile compared to traditional ships though they pay for this by being more expensive and requiring more maintenance.

Despite the arrival of the advanced azimuth thrusters, many warships still continue to utilize traditional rudders. These simpler arrangements provide the high speed and reliability needed for combat situations. The loss of agility is partially made up by the use of thrusters in the bow or even azimuth pods. Rudders have long been a staple in warship construction. Even with the arrival of new technologies, it looks as if rudders will be around for decades to come!

Final Words

I know that rudders are a relatively boring piece of technology. However, I want to eventually dicuss every aspect of a warships design. It was only a matter of time before I had to look at the rudder. Next time, I will pick out something a bit more exciting! Until next time!

Further Links

Want to follow Navy General Board on Social Media? Check us out on the platforms below!

Help the Website grow by purchasing a Navy General Board Shirt!

- Parler

- YouTube

- The Navy General Board Forum

- Want to help the site continue to expand? Support us on Patreon.

- Learn more about how NGB got started!

More Great Articles

Check out our collection of articles. Some of our latest articles include:

The Enterprise CVN 65 most assuredly had exactly four rudders one behind each of its four shafts. Rudders 1 & 4 outboard starboard and port respectively. However rudders 1 & 4 were inclined ~25 degrees from vertical as they were intended to act as stabilizers for flight deck. As costs rose McNamara had the associated stabilizer control system removed but it was too late to remove the rudders. As a consequence of not being vertical , rudders 1&4 developed hydrodynamic lift as water passed over the inclined surfaces. This lift had the unintended effect tilting the rudder king posts such that the post pushed towards seal on one side and away from seal on the other. The net result was that at higher speeds the posts leaked water into the inner bottom. A simple solution came to mind as seal was only about 30 ft below water line. Low pressure air of about 15 psi was bled into inner bottom void to offset water pressure. As A Div officer I went into inner bottoms voids while in Newport News to inspect the seal and rudder king posts.

Now that is some interesting information! Thank you very much for sharing your experiences with us.